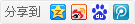

Our company manufacturing production line equipment Geocell is determined by more than one combination of ultrasonic plastic welding machine adopts imported PLC control has the following advanced features:

1, touch-screen display and parameter setting, imported piezoelectric ceramic transducer, the output strength and stability.

2, color display touch-screen control panel.

3, all-Chinese menu, with multi-language you set, easy to use.

4 levels of adjustable mold design, mold fast and easy adjustment.

2, color display touch-screen control panel.

3, all-Chinese menu, with multi-language you set, easy to use.

4 levels of adjustable mold design, mold fast and easy adjustment.

5, the new power amplifier circuit, power is more robust, more durable transducers,

6, frequency automatic tracking, a variety of parameter settings. High degree of automation in the domestic production of similar products in the leading position.

6, frequency automatic tracking, a variety of parameter settings. High degree of automation in the domestic production of similar products in the leading position.

Geocell equipment specifications sheet

|

Geocell welding mold-digit

|

HJM-11

|

HJM-14

|

HJM-18

|

HJM-22

|

|

No.of welding heads

|

11 unit

|

14 unit

|

18 unit

|

22 unit

|

|

Max. Power

|

28.6KW

|

36.4KW

|

46.8KW

|

57.2KW

|

|

Ultrasonic Vibrating Power

|

16.5KW

|

21KW

|

27KW

|

33KW

|

|

SIZE OF THE EQUIPMENT (L*W*H)(M

|

6.5*1.89*2.26

|

7*1.89*2.26

|

8*1.89*2.26

|

9*1.89*2.26

|

|

WEIGHTNESS

|

5TONS

|

5.5TONGS

|

6TONS

|

6.5TONS

|

|

POWER

|

AC380V N 50-60HZ

|

|||

|

AIR PRESS

|

0.6~0.9MPa

|

|||

|

AIR COMPESSOR DISPLACEMENT

|

≥2.5~3.0/min

|

|||

|

VOLOUM OF AIR COMPRESSOR AIR STORAGE

|

1.5~2.0M3

|

2.5~3.0M3

|

||

|

WELDING DISTANCE SCOPE

|

220-1000mm

|

|||

|

GEOCELL STRIP WIDTH

|

220MM MAX (ADJUSTABLE ACCORDING TO THE SIZE OF WELDING HEAD)

|

|||

|

DAILY OUTPUT (REF)

|

4500SQM

|

4800SQM

|

5200SQM

|

8000SQM

|